Steel Shots for Water Jets & Water Tanks

Water is an essential commodity that is required by everyone, and in order to ensure that it is safe for consumption, it is necessary to store it in water tanks. However, over time, the water tanks and water jets can accumulate rust, algae, and other impurities, which can make the water unsafe to drink. That's where steel shots come in.

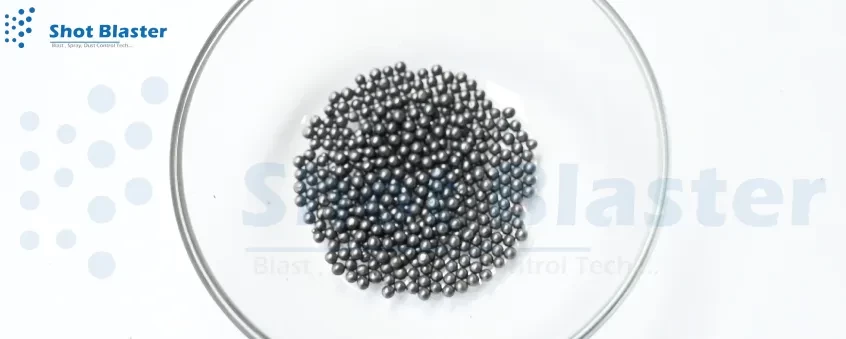

Steel shots are small spherical pellets made of steel that are used for a variety of purposes, including cleaning and preparing surfaces for painting. In this blog post, we'll explore how steel shots can be used to clean water jets and water tanks and why they are the preferred choice for this task.

What are steel shots?

Steel shots are small, round pellets made of steel. They are created by melting steel and pouring it into a mold, which is then cooled and broken into small, uniform-sized pieces. Steel shots are used in a variety of industries, including automotive, aerospace, and construction. They are also used for cleaning and preparing surfaces for painting.

Why use steel shots for water tanks and jets?

Steel shots are the preferred choice for cleaning water tanks and jets because they are highly effective at removing rust, algae, and other impurities. They are also environmentally friendly and can be reused, making them a cost-effective solution for cleaning large water storage containers.

How do steel shots clean water tanks and jets?

When steel shots are fired at a surface, they create a peening effect. This effect causes the surface to be compressed, which in turn removes any rust, scale, or other impurities that may be present. Steel shots are particularly effective at removing rust, which can be a major problem in water tanks and jets. The peening effect also creates a rough surface, which is ideal for painting or coating. This rough surface allows paint or coating to adhere more effectively, which ensures that the tank or jet remains protected for a longer period of time.

Safety considerations when using steel shots

While steel shots are highly effective at cleaning water tanks and jets, it's important to take the necessary safety precautions when using them. Steel shots can be dangerous if they are not handled properly, and they can cause serious injury if they come into contact with skin or eyes.

To ensure safe use of steel shots, it's important to wear protective gear such as safety glasses, gloves, and a dust mask. It's also important to use the appropriate equipment, including a Sand blasting cabinet, air compressor, and a dust collector.

Types of steel shots

There are two main types of steel shots: cast and cut. Cast steel shots are made by melting steel and pouring it into a mold, while cut steel shots are made by cutting steel wire into small pieces. Both types of steel shots are effective for cleaning water tanks and jets, but cast steel shots are more durable and can be reused more often than cut steel shots.

Steel shot size

Steel shots come in a variety of sizes, ranging from very fine to very coarse. The size of the steel shot you choose will depend on the type of surface you're cleaning and the level of cleaning you need to achieve. Fine steel shots are typically used for light cleaning and preparing surfaces for painting, while coarse steel shots are used for heavy-duty cleaning and surface preparation.

Steel shot recycling

One of the benefits of using steel shots for cleaning water tanks and jets is that they can be reused. Steel shots that are not damaged or deformed during the cleaning process can be collected, cleaned, and reused. This makes steel shots a cost-effective solution for cleaning large water storage containers.

However, it's important to note that steel shots that are damaged or deformed during the cleaning process should be disposed of properly. This typically involves recycling the steel shots or disposing of them in accordance with local regulations.

Alternatives to steel shots

While steel shots are highly effective at cleaning water tanks and jets, they are not the only solution. Other alternatives include sand blasting, soda blasting, and water blasting. Each of these methods has its own advantages and disadvantages, and the best method to use will depend on the specific requirements of the job.

For example, sand blasting machine is highly effective at removing rust and scale, but it can also create a lot of dust, which can be a health hazard. Soda blasting is less dusty than sandblasting, but it can be more expensive. Water blasting is a good option for cleaning delicate surfaces, but it may not be effective for heavy-duty cleaning.