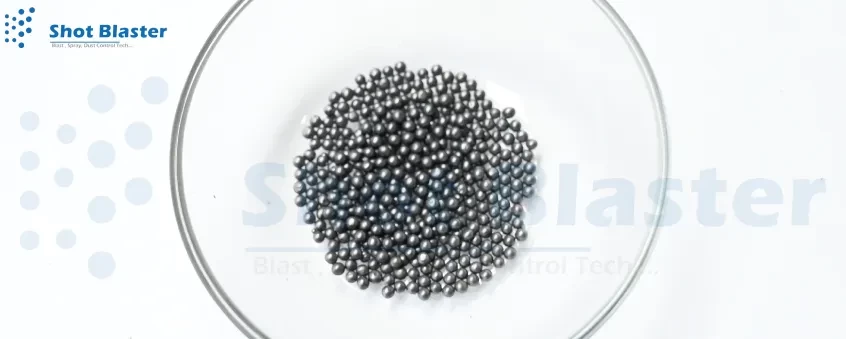

Steel shots for descaling

|

hardness |

450 - 550 HV |

|

Density |

7.51 g / ml Min. |

|

Chemical compositions |

- |

|

Carbon |

0.6 to 1.25% |

|

Silicon |

0.2 to 1.1 |

|

Manganese |

1.25% Max. |

|

Sulphur |

0.08% Max. |

|

Phosporus |

0.08% Max. |

Steel shots for descaling are popularly used in the industry. One of the most important applications for our magnificent abrasive medium is the descaling of forged steel with steel shots. Steel shots for descaling is a metal cleaning process that removes unwanted surface deposits from metals to create a smooth surface finish. Steel shots for descaling are one of the pre-finishing techniques, along with cleaning, stripping, and pickling. Cleaning and pickling are used in these methods to remove scale.

Steel shots for descaling hence not only cut down on the extra labor-intensive and expensive metal cleaning processes. Among all the powerful abrasive media utilized in the market, steel shots are such an incredible grade of abrasive that they have a set of proportions that are constant. The steel shots are thought to be between 450 and 550 HV in hardness. The density of the steel bullets is 7.1 g/ml minimum on average. Steel bullets frequently include between 0.6 and 1.25% carbon, between 0.2 and 1.1% silicon, between 1.25% manganese, and between 0.08% sulfur and 0.08% phosphorus. We also provide sand blasting safety equipment for the successful blasting procedures with all kind of airless and air operated sand blasting machines.

Steel shots price range set by our company is more than affordable. As a well-known brand in the industry, we offer steel shots price ranges that is both reasonable and justified given the caliber of the services we offer. We offer the most competitive steel shots price ranges on the market for the entire dispatched range of steel shots. Additionally, the price range of our portable shot blasting machines and other sand blasting machines is actually more than enough. As a profound manufacturer our price ranges of other products such as automatic sand blasting machine, grit blasting machine, dustless blasting machine and vacuum blasting machine.

Steps for manufacturing steel shots in India

- At a very early stage, Metal waste made of alloy and steel is first melted.

- Then, to atomize them all together, high-pressure water jets are employed.

- The obtained object has to be dried as the following stage.

- After the drying process is finished, the separation and screening of different steel shot sizes begin.

- Spiraling then begins. This is the process of removing steel shots with odd forms.

- Quenching is the following phase, which is utilised to further produce particles with greater integrity and the fewest stress fractures.

- Tempering screening is done to confirm the product's quality and requirements prior to packing.

- The finished steel shots are finally bagged and boxed.

Steel Shots in India

Steel shots in India is a very popular choice amongst all the competitive price range In India, shot blasting is frequently employed in all sophisticated utilities. To preserve tools and equipment in the best possible condition and to ensure optimal machine performance, heat treatment of metal machines and components is required. Steel shots in India are therefore the best option for the heat-treated product.

As time passes, it's possible to see that soft metals turn into hard metals while hard metals turn into soft metals, or that rust and corrosion may lead to faulty equipment, which negatively impacts how work with such metals is done. Such a negative effect results in the low productivity that your metal tools and components may otherwise produce. Steel shots for heat treatment, however, can repair the metal's flawed or impacted within steel shots in India. For any details regarding the price ranges of our sand blasting hopper please visit our website.

We are one of the most profound manufacturers of Portable sand blasting machine, dustless blasting machine, portable shot blasting machine and pressure blasting cabinet. As profound steel shots manufacturers, we have the utmost caliber of being responsible for the entire supremacy of quality products from our sense of production. We offer all of our clients competitive price ranges based on the services and time of delivery. As a profound manufacturers, we assure you that all the leading grades provided by us should withstand the expectations of our respective clients.

Our leading grades withstand moreover a compact grade of the vast variety of sand blasting machines. A vast range of our products included all kinds of blasting cabinets, blasting machines such as portable shot blasting machines, vacuum blasting machines, and many more at affordable prices in the market. Steel shots are one such abrasive that offers a wide range of advantages that offers varied applications. As such as steel shots for peening as well as for etching, dirt removal, contamination removal, heat treatment and many others.

Steel Shots Pros

As we are well aware, steel shots are one of the most specified forms of abrasive media that have applications in all kinds of expertise. The majority of the surface is covered by steel shots in spherical and granular shapes. Steel shots have such a hard surface that makes them versatile, durable, as well as cost-efficient. Cut wire shots have such a versatile grade that makes them super resistant to wear and tear as well as ensures their better performance overall categories of workpieces. We also provide a vast range of arc spray guns such as thermal spray gun and many others.

Steel shots are such an amazing product that reduces surface tensions as well as provides a durable touch for paint removal as well as solves the problem of paint flaking. Being used in continuous cycles, steel shots are in fact more environment-friendly. We as a profound manufacturer also produce a vast range of other products as such as portable shot blasting machine, pressure blasting cabinet, suction blasting cabinet, and dustless blasting machine.

Steel Shots Applications

- Steel shots have the advantage of requiring less frequent machinery maintenance. It produces an incredibly flawless and smooth surface.

- The material's (steel shots) remarkable toughness and long lifetime contribute to its competitive pricing.

- Steel shot’s exceptional recycling capacity also results in less material waste being created. A surface needs to be washed, sanded, and physically modified before blasting.

- Steel shot and grit are widely used in surface preparation to physically modify the metal surface, for example, by making it rougher, to improve the application of paint and coating, as well as to clean metal surfaces that are covered with mill scale. For any details regarding price ranges of sand blasting machine please visit our website.

Steel Shots Characteristics

In the end, steel shots are spherical balls of molten metal. Steel shots are perfect for cleaning surfaces because of their well-defined form. The steel bullets cover a large amount of ground. Steel shot peening, forging, and shot blasting are among the most versatile and resilient abrasives, both in terms of their lifetime and the caliber of treatments they can provide. Hammer strikes, equipment for shot blasting, or laser peening are examples of mechanical procedures. Steel shots for abrasive blasting are one of the most profound as well as popular applications of steel shots in the market.